Fasteners and Machining: Secret to Efficient and Trustworthy Manufacturing

Fasteners and Machining: Secret to Efficient and Trustworthy Manufacturing

Blog Article

Opening the Prospective: Fasteners and Machining Solutions for Seamless Procedures

In the intricate landscape of commercial operations, the function of bolts and machining services often goes undetected, yet their value in making sure efficient and smooth processes can not be overstated. The mindful selection of bolts and the utilization of accurate machining strategies are critical in attaining a seamless integration that can elevate functional efficiency to brand-new elevations. By diving right into the world of bolts and machining remedies, a globe of untapped capacity and boosted productivity awaits those who are eager to discover the opportunities that lie within.

Significance of Selecting the Right Bolts

Picking the appropriate fasteners is vital for ensuring the structural integrity and longevity of any assembly. The option of fasteners can substantially influence the performance and reliability of the end product. By using the best fasteners, suppliers and engineers can enhance the overall quality of the setting up and reduce the dangers of failure or premature wear.

One key consideration when choosing fasteners is to match the product of the fastener with the materials being signed up with. Compatibility in between the substrate and the fastener is necessary to prevent rust and guarantee a safe link.

Enhancing Precision With Machining Solutions

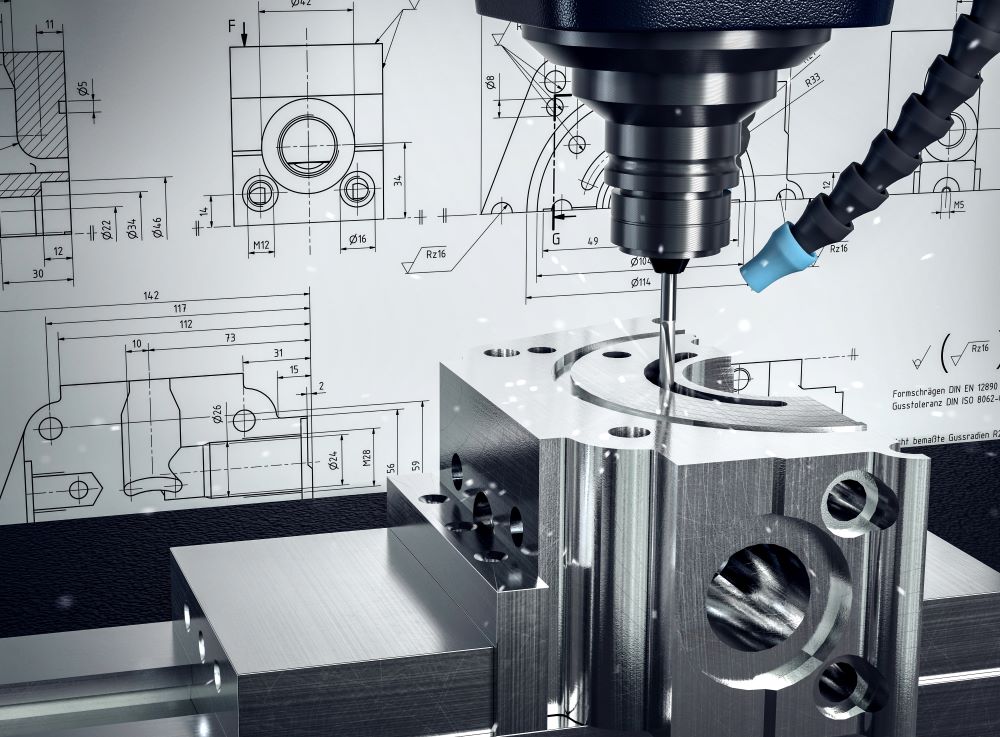

Utilizing sophisticated machining services can dramatically enhance the precision and effectiveness of producing procedures. Accuracy in machining is crucial for guaranteeing that elements meshed perfectly, reducing the requirement for rework and improving the general high quality of the last item. By leveraging innovative machining modern technologies such as Computer system Numerical Control (CNC) equipments, suppliers can attain limited resistances and complex layouts easily.

In addition, progressed machining remedies provide abilities such as multi-axis machining, high-speed cutting, and integrated automation, which improve manufacturing procedures and enhance overall accuracy. These technologies allow producers to generate intricate get rid of marginal mistake, bring about higher performance and price savings in the lengthy run.

In addition to precision, machining remedies likewise play a crucial function in improving uniformity across production sets. By programming machining processes to precise specifications, manufacturers can reproduce the exact same top notch results consistently, ensuring harmony in the final items. In general, purchasing sophisticated machining solutions is essential for makers wanting to elevate their accuracy capabilities and accomplish seamless procedures.

Optimizing Efficiency in Operations

Enhancing functional effectiveness is extremely important for optimizing productivity and lessening costs in producing processes. Enhancing procedures through effective usage of resources, maximizing workflows, and reducing downtime are crucial for accomplishing this objective. One vital aspect of taking full advantage of performance in operations is carrying out lean production principles. By eliminating waste, systematizing procedures, and continuously improving operations, firms can boost their overall effectiveness.

Making use of innovative modern technologies such as automation, robotics, and information analytics can additionally play a significant why not try this out role in optimizing operations (Fasteners and Machining). These modern technologies can help in reducing manual work, boost precision, and give real-time understandings for better decision-making. Furthermore, buying employee training and advancement can improve ability degrees and make sure that employees are geared up to manage tasks effectively

Working together closely with suppliers to streamline supply chains and implementing just-in-time supply systems can better improve effectiveness by decreasing lead times and decreasing excess stock. In general, by concentrating on taking full advantage of efficiency in procedures, companies can enhance their competition, enhance customer satisfaction, and attain lasting growth in the long-term.

Seamless Assimilation of Bolts and Machinery

To attain smooth combination, producers need to carefully select bolts that fulfill the certain demands of the machinery being assembled. Variables such as product compatibility, dimension, rust, and strength resistance are crucial considerations in picking the right fasteners. In addition, using advanced machining strategies and innovations can even more enhance the assimilation process by making certain exact fitting and placement of fasteners within the equipment elements.

Effect On Efficiency and High Quality

The seamless integration of bolts and machinery considerably impacts both performance and top quality in producing operations. By carefully picking the ideal fasteners and machining remedies, suppliers can enhance their production procedures, causing enhanced efficiency and result. Premium fasteners make visit this site right here certain that elements are firmly held together, reducing the chance of errors or issues in the final item. This, consequently, enhances the total quality of the made goods, conference or even going beyond customer assumptions.

Final Thought

To conclude, choosing the appropriate bolts and machining services is crucial for enhancing procedures and enhancing productivity. The assimilation of these components can significantly affect the performance and high quality of procedures. By thoroughly taking into consideration the compatibility and precision of bolts and equipment, seamless procedures can be achieved, bring about enhanced general efficiency and success in different sectors.

In the intricate landscape of industrial procedures, the function of bolts and machining services usually goes unnoticed, yet their importance in making certain reliable and smooth procedures can not be overstated.One essential factor to consider when picking fasteners is to match the material of the fastener with the products being signed up with. In addition, utilizing advanced machining methods and innovations can better improve the integration procedure by ensuring specific suitable and alignment of fasteners within the equipment components.

By carefully selecting the best fasteners and machining options, suppliers can simplify their manufacturing procedures, leading to increased efficiency and output. Precision machining ensures that components are accurately processed, fitting with each other seamlessly with bolts for a reputable and exact end product.

Report this page